DeHoff Machines Features & Options

Our DeHoff machines feature a robust high-pressure coolant system, a PC-based control system, and various fixturing options to suit your needs. These machine systems are designed, engineered, and manufactured in-house for unsurpassed performance and reliability.

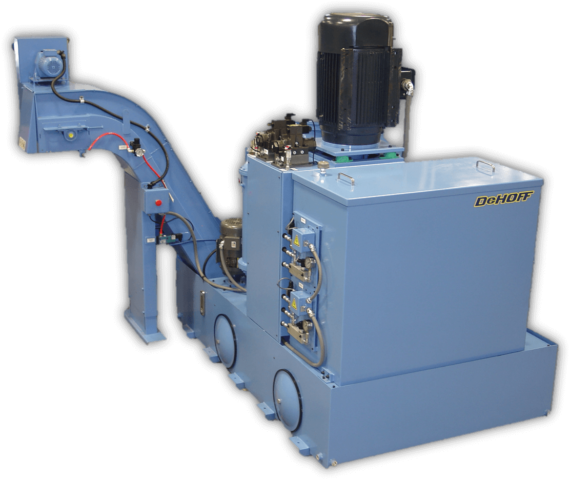

Coolant System

DeHoff high-pressure coolant systems are extremely robust and can handle either oil or water-soluble coolants. The coolant tank has a capacity of up to 500 gallons (1893 L), and features a twin tank system with a separate clean tank and dirty tank.

The coolant system features an optional chip conveyor to separate the larger metal chips from the cutting fluid. Chip conveyors are available as either magnetic or flighted type, and 6 or 12 inches (152 or 305 mm) wide. The system also has twin filter canisters for additional filtration, which are equipped with pressure switches to indicate clogged filters.

The temperature of the cutting fluid is controlled by a shell-and-tube heat exchanger, which can use water from the facility or Glycol from an external chiller unit. Coolant system parameters such as flow, temperature, and pressure can be monitored and adjusted from the machine control panel.

Coolant System Specifications

| Tank Capacity | Up to 500 gallons (1893 L) |

| Coolant Flow Rate | Up to 160 gpm (606 L/min) |

| Pump Motor | Up to 50 hp (37.3 kW) |

| Coolant Pressure | Up to 2,500 psi (172 bar) |

| Filtration | 10µ (microns) |

Machine Control

DeHoff machines use an embedded PC-based controls system featuring Beckhoff Controls. This system emulates the typical PLC-based control while also providing features commonly associated with a PC.

Beckhoff Controls use the Microsoft Windows® OS with built-in Ethernet capability. The system utilizes a solid-state disk drive instead of a typical PC magnetic hard drive. This results in no moving parts and increased reliability in a production environment.

The control system also features a robust EtherCat communication technology for high-speed interface with the machine spindle and servo drive, resulting in dynamic performance of the servo system.

Machine Control Features

- Full color 12-inch (305 mm) display

- Built in calculator for cutting parameters

- Part program storage

- FAQ built into the interface

- Multiple fault readout

- Spindle speed and feed rate override while in automatic cycle

- Machine failure diagnostics via remote industrial Ethernet communication

- Modular components for quick change out (comparable to rack mounted PLC)

- Manual pulse generator for remote axis activation, resulting in enhanced machine setup capability

- Remote coolant pressure control

- CNC G-Code programming available on Multi-Axis machines

The Beckhoff Controls package is also available for control retrofits, either as a field installation or as part of a full factory machine rebuild.

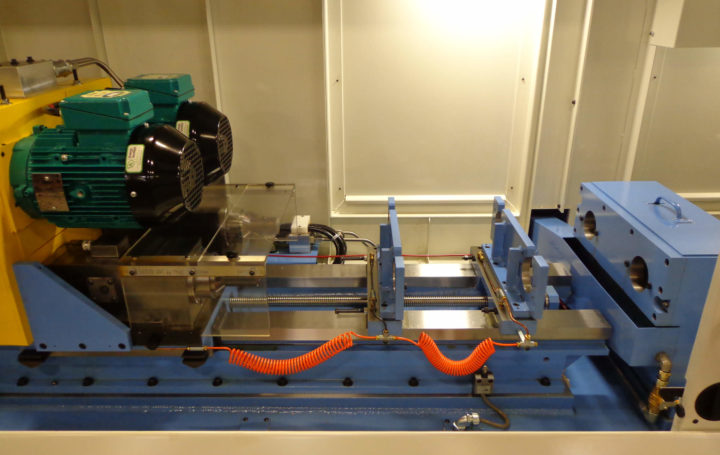

Fixturing Options

DeHoff machines offer various workpiece handling options to accommodate the different lengths and diameters of customer parts.

Fixturing options include:

- 6 Jaw Chuck – 10-inch (254 mm) diameter with a 3-inch (76 mm) thru-hole, fitted to the face of the chip box for fixturing cylindrical workpieces.

- 3 Jaw Tailstock – 8-inch (203 mm) diameter with a 2.56-inch (65 mm) thru-hole is fitted to an angle plate weldment. This tailstock is keyed to a fixture plate on the bed of the machine to maintain proper alignment. A breakthrough attachment contains the oil when drilling through the end of the part.

- Part Counter Rotation – Counter rotation is installed using an 8-inch (203 mm) 3-jaw chuck on the tailstock. The tailstock is mounted to a T-slot plate together with an adjustable V-rest to help locate the part at the chipbox.

- Hydraulic 3 Roller Rest – The hydraulic 3 roller self-centering rest is mounted so it can be positioned on the T-slot plate. It includes a hydraulic power unit and all plumbing and electrical. Capacity 0.5-inch (12mm) to 4.72-inch (120mm) part diameter.

- Manual 3 Roller Rest – A manually adjustable 3 roller rest with swing open top is mounted so it can be positioned on the T-slot plate. Capacity 0.5-inch (12mm) to 5.5-inch (140mm) part diameter.

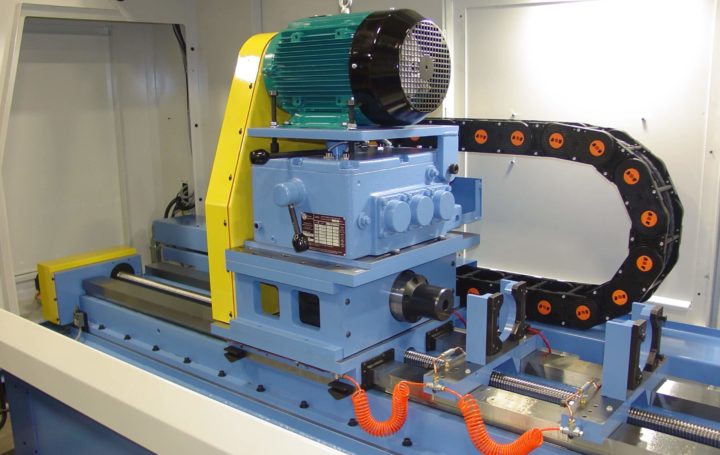

High-Torque Gearbox

Available on the DeHoff 20 Series, the High-Torque Gearbox enables the operator to change the spindle torque with the pull of a lever, instead of a time-consuming belt and pulley changeover. It is also able to deliver up to twice the torque of a standard duty machine. The High-Torque Gearbox is ideal for the drilling of high temperature material where low surface speeds are required, yet high torque at the spindle is also necessary.

Included in the option is a 4-speed transmission gearbox, manual change with proximity sensors for range display, heavy duty spindle assembly and pulleys, belts, and 2:1 feed drive gearbox for increased feed thrust. No spindle pulley change is needed.

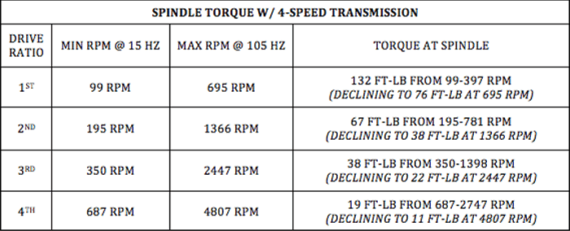

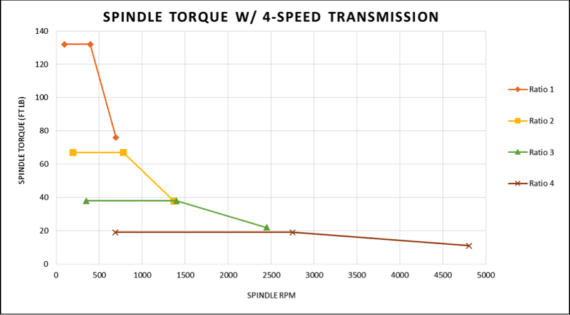

Spindle Torque w/ 4-Speed Transmission