Used by over 60 firearms companies globally.

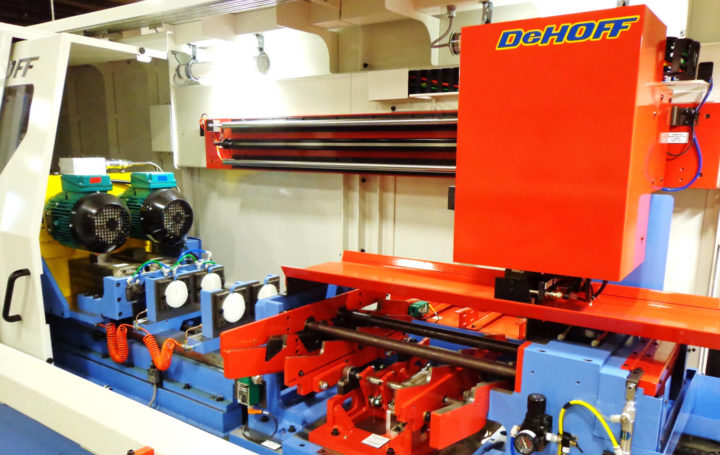

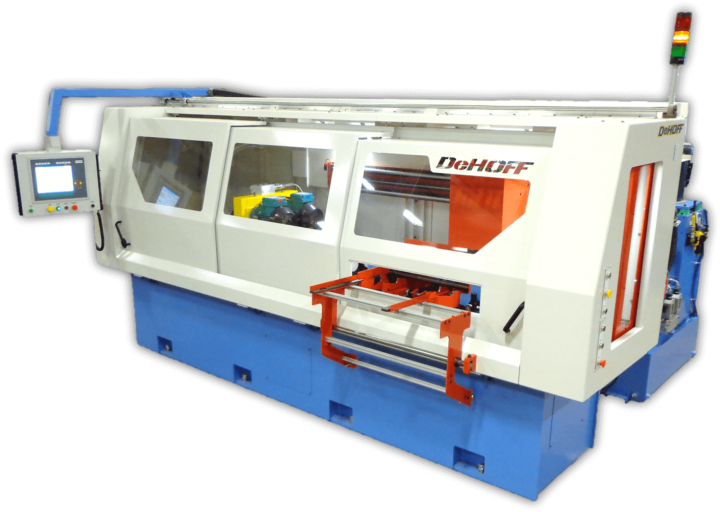

The Gun Barrel line of machines from DeHoff are specifically designed for the manufacture of gun barrels. We offer several different types of machines with options for caliber size, barrel length, and number of spindles to meet your particular barrel manufacturing needs.

Our full turnkey package of equipment can be tailored to fit most any budget or production goal, and includes:

- Gundrilling Machines – up to 4 spindles

- Reaming Machines – up to 6 spindles

- Gundrilling + Reaming 2-in-1 Machines

- Button Rifling Machines

- Cut Rifling Machines

- Tooling – gundrills, reamers, rifle buttons

- Stress Relieve Oven with automated loading system

- Gauging Equipment

DeHoff gun barrel machines are used by over 60 firearms companies all over the world. To get started with a complete gun barrel manufacturing system, contact Ed Kays at (660) 886-9929 or [email protected].

Watch:

The DeHoff Advantage:

Unmatched performance

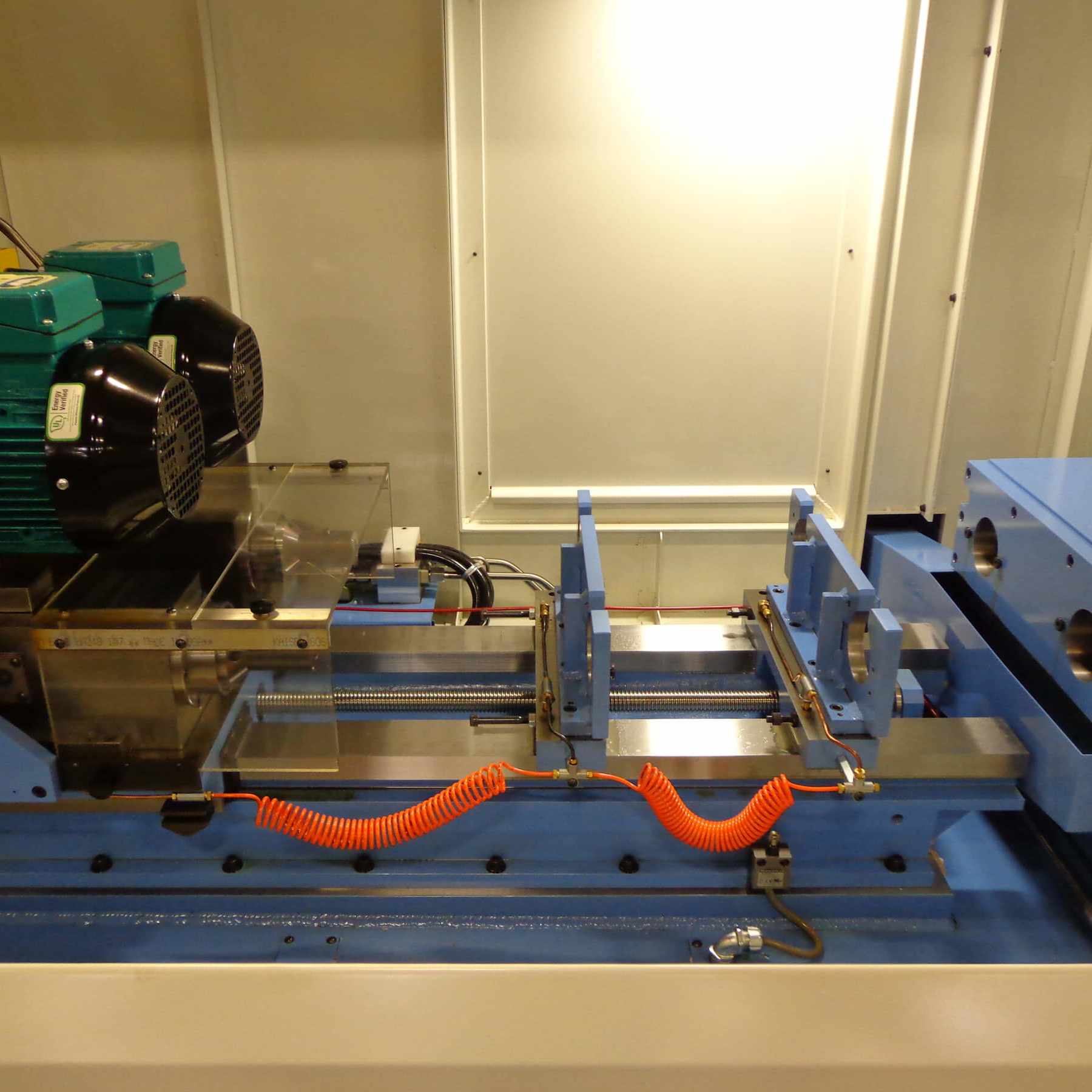

Hardened and ground steel box ways with hand-scraped saddle, gibs, and straps provide long-term drilling accuracy and reliability.

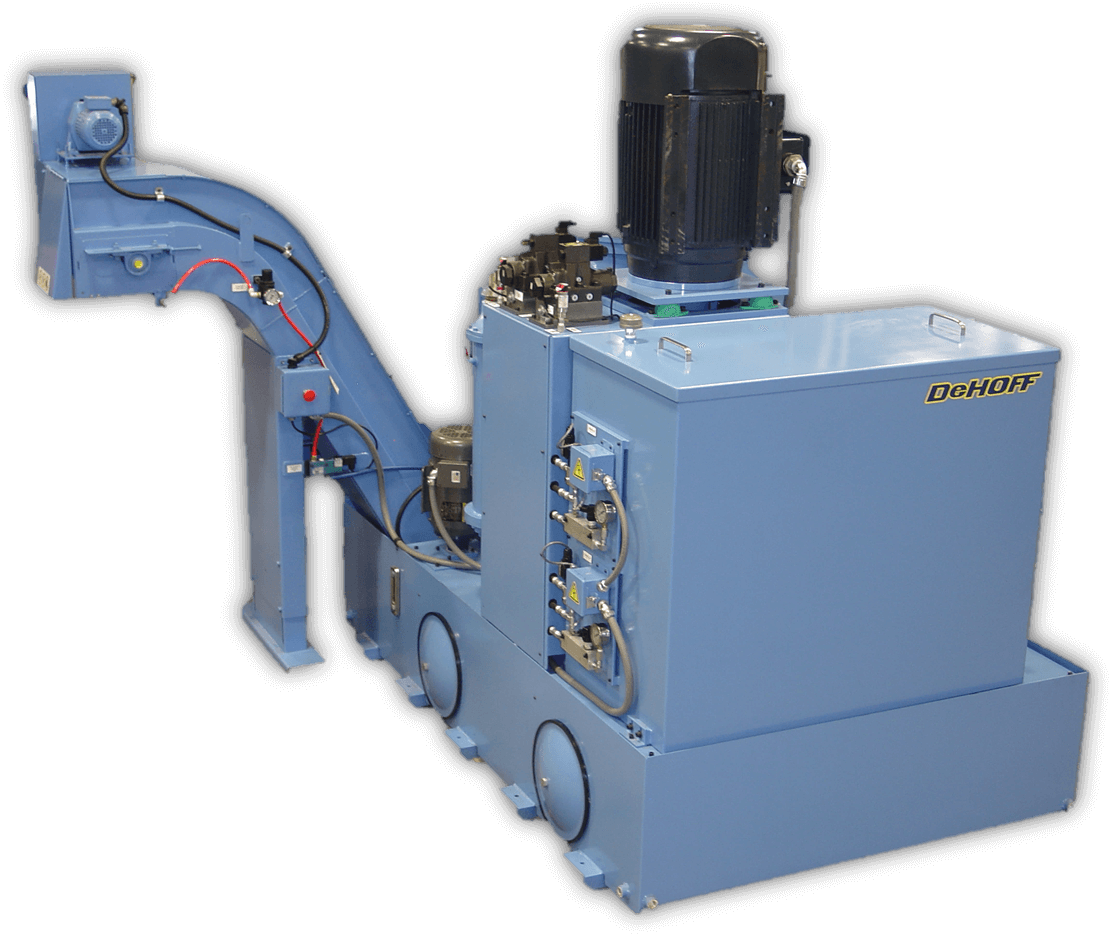

Robust coolant system

High-pressure coolant system is suitable for either oil or water-soluble coolants up to 2,500 psi (172 bar) or 160 gpm (606 L/min).

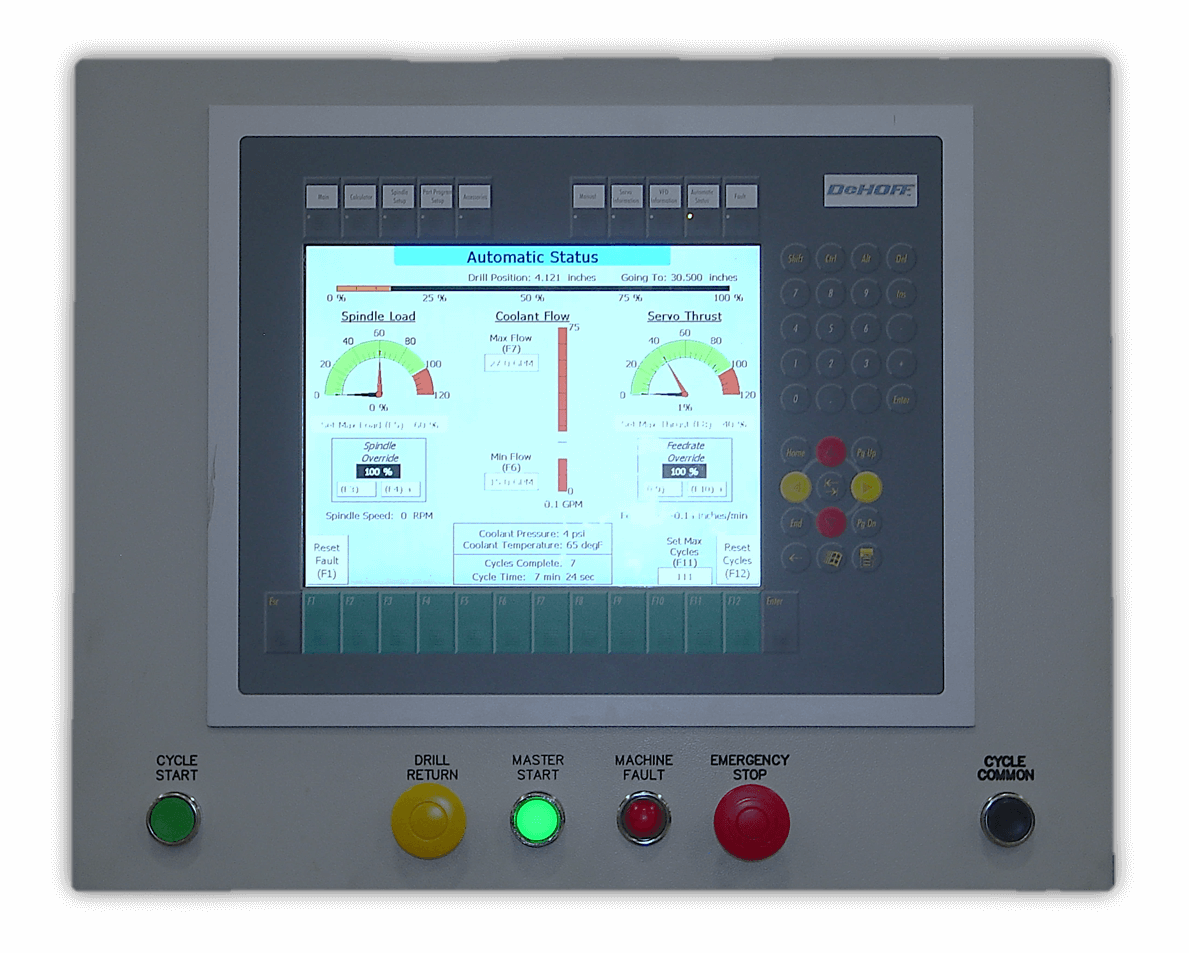

PC-Based machine controls

Embedded PC-based control system features Microsoft Windows OS and a 12-inch (305 mm) color display.

Versatile workpiece handling

Custom fixturing and automated part loading options available.

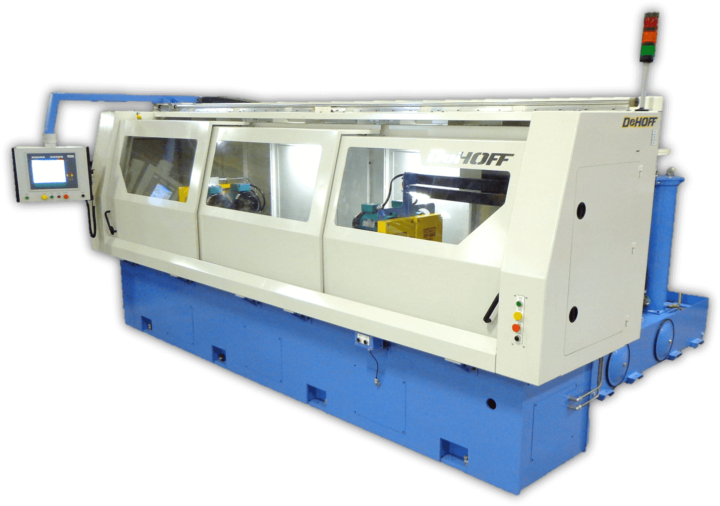

G560-DR2

Gun Barrel Drilling & Reaming

| Drill Capacity | 17 – 50 caliber |

| Slide Travel | 36 in (914 mm) or 60 in (1524 mm) |

| No. of Spindles | 2 |

| Spindle Power | 5 hp (3.7 kW) |

| Spindle RPM | 1,000 – 8,000 |

| Feed Rate | 0.1 – 30 in/min (2.5 – 762 mm/min) |

| Coolant Flow | 60 gpm (227 L/min) |

| Coolant Pressure | 1,800 psi (124 bar) |

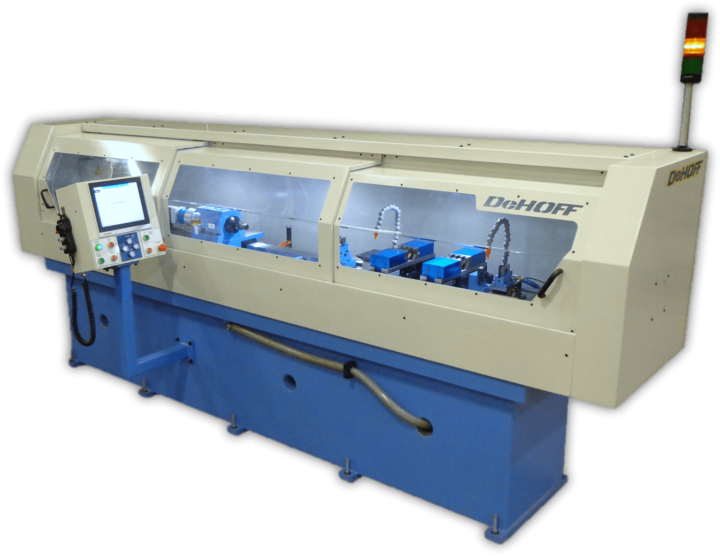

G560-B1

Gun Barrel Button Rifling

| Capacity | 17 – 50 caliber |

| Slide Travel | 60 in (1524 mm) |

| No. of Spindles | 1 |

| Twist Rate | 1 in 5 inches – 1 in 60 inches (1 in 127 mm – 1 in 1524 mm) |

| Pull Speed | 0 – 100 in/min (0 – 2540 mm/min) |

| Pull Force | 25 ton max (222 kN max) |

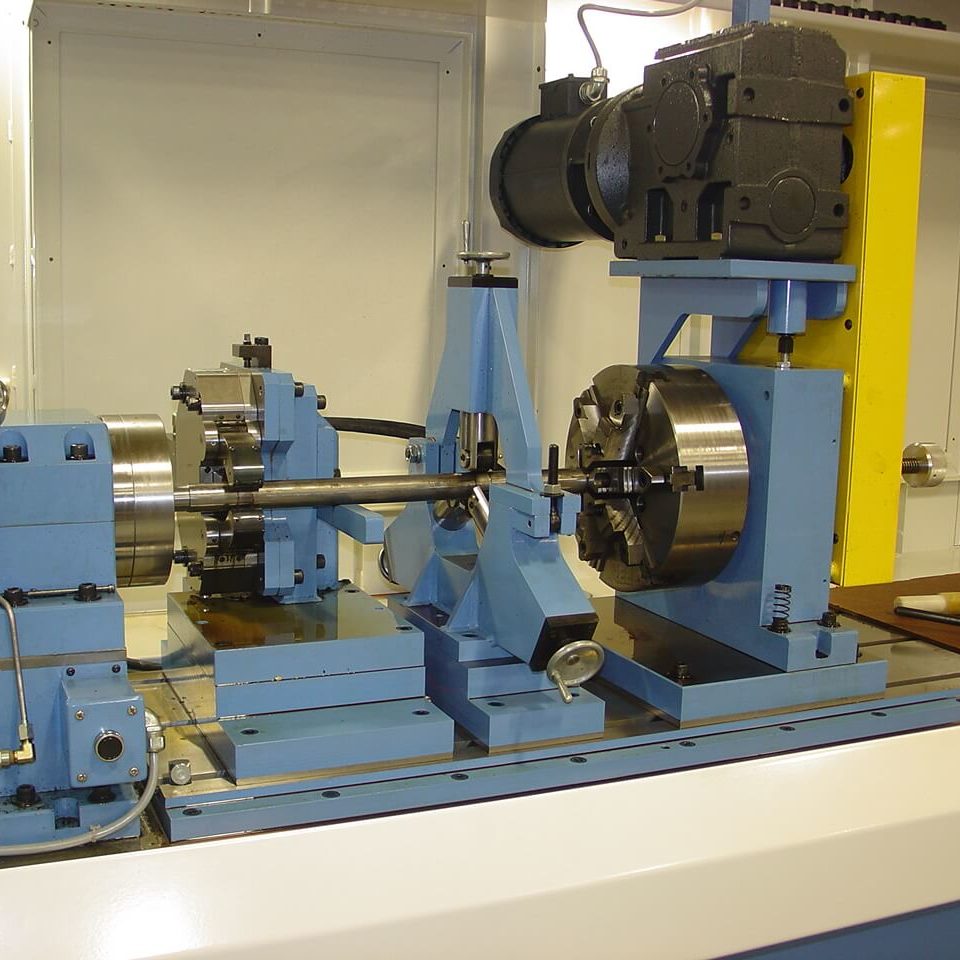

G536-C1

Gun Barrel Cut Rifling

| Capacity | 22 – 50 caliber |

| Slide Travel | 36 in (914 mm) |

| No. of Spindles | 1 |

| Barrel Length | 4 – 30 in (102 – 762 mm) |

| Twist Rate | 1 in 4 inches – 1 in 60 inches (1 in 102 mm – 1 in 1524 mm) |

| Programming | Variable twist rates (gain twist) |

| Pull Speed | 0 – 400 in/min (0 – 10,160 mm/min) |

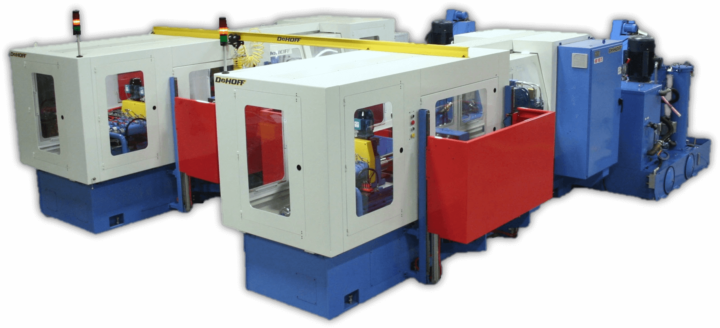

G548-D4

Gun Barrel Drilling w/ Automation

| Capacity | 17 – 50 caliber |

| Slide Travel | 48 in (1219 mm) |

| No. of Spindles | 4 |

| Spindle Power | 7.5 hp (5.6 kW) |

| Spindle RPM | 1,300 – 7,800 |

| Feed Rate | 0.1 – 30 in/min (2.5 – 762 mm/min) |

| Coolant Flow | 60 gpm (227 L/min) |

| Coolant Pressure | 2,000 psi (138 bar) |

| Automation | Lift-and-Carry |

| Part Loading | Magazine (40-48 barrels) |

G560-D Cell

Gun Barrel Drilling Cell

| Capacity | 50 caliber |

| Slide Travel | 60 in (1524 mm) |

| No. of Spindles | 4 |

| Spindle Power | 3 hp (2.2 kW) |

| Spindle RPM | 900 – 2,400 |

| Feed Rate | 0.1 – 30 in/min (2.5 – 762 mm/min) |

| Coolant Flow | 60 gpm (227 L/min) |

| Coolant Pressure | 2,000 psi (138 bar) |

| Automation | Lift-and-Carry |

G560-R2

Gun Barrel Reaming

| Capacity | 17 – 50 caliber |

| Slide Travel | 48 in (1219 mm) or 60 in (1524 mm) |

| No. of Spindles | 2 |

| Spindle Power | 3 hp (2.2 kW) |

| Spindle RPM | 400 – 11,800 |

| Feed Rate | 0.1 – 30 in/min (2.5 – 762 mm/min) |

| Coolant Flow | 20 gpm (75.7 L/min) |

| Coolant Pressure | 1,000 psi (68.9 bar) |

G534-R6

Gun Barrel Reaming

| Capacity | 17 – 50 caliber |

| Slide Travel | 34 in (864 mm) |

| No. of Spindles | 6 |

| Spindle Power | 3 hp (2.2 kW) |

| Spindle RPM | 200 – 2,600 |

| Feed Rate | 0.1 – 40 in/min (2.5 – 1016 mm/min) |

| Coolant Flow | 60 gpm (227 L/min) |

| Coolant Pressure | 2,000 psi (138 bar) |