Kays Engineering meets your unique applications and requirements.

We design and build custom DeHoff gundrilling machines. These machines feature custom fixturing, automated workpiece loading/unloading, and unique spindle configurations.

If you’d like to learn more about how we can customize a machine for you, please contact Ed Kays at 660-886-9929 or [email protected].

Examples of customized DeHoff machines

218 4-Spindle

- Custom machine for gundrilling hollow stem engine values

- Gundrilling capacity = 0.25 inches (6.4 mm)

- Max depth = 18 inches (457 mm)

- 4 spindles

- Automated workpiece loading / unloading

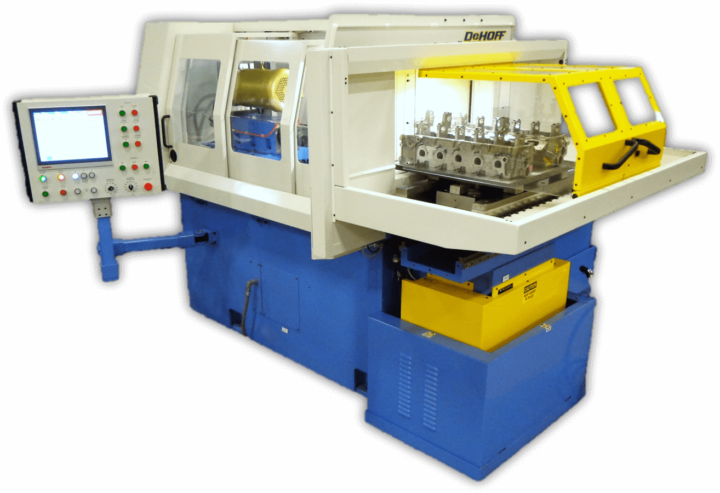

1024C 6-Spindle

- Custom machine for gundrilling camshafts

- Gundrilling capacity = 1 inch (25.4 mm)

- Max depth = 24 inches (610 mm)

- 6 spindles

- Lift-and-Carry material handling automation

- Adjustable tailstocks/hydraulic clamping system

1536 Twin Slide

- Custom machine for gundrilling helicopter drive shafts

- Gundrilling capacity = 1.5 inches (38.1 mm)

- Max depth = 36 inches (914 mm)

- 2 spindles on independent slides with dual operator controls

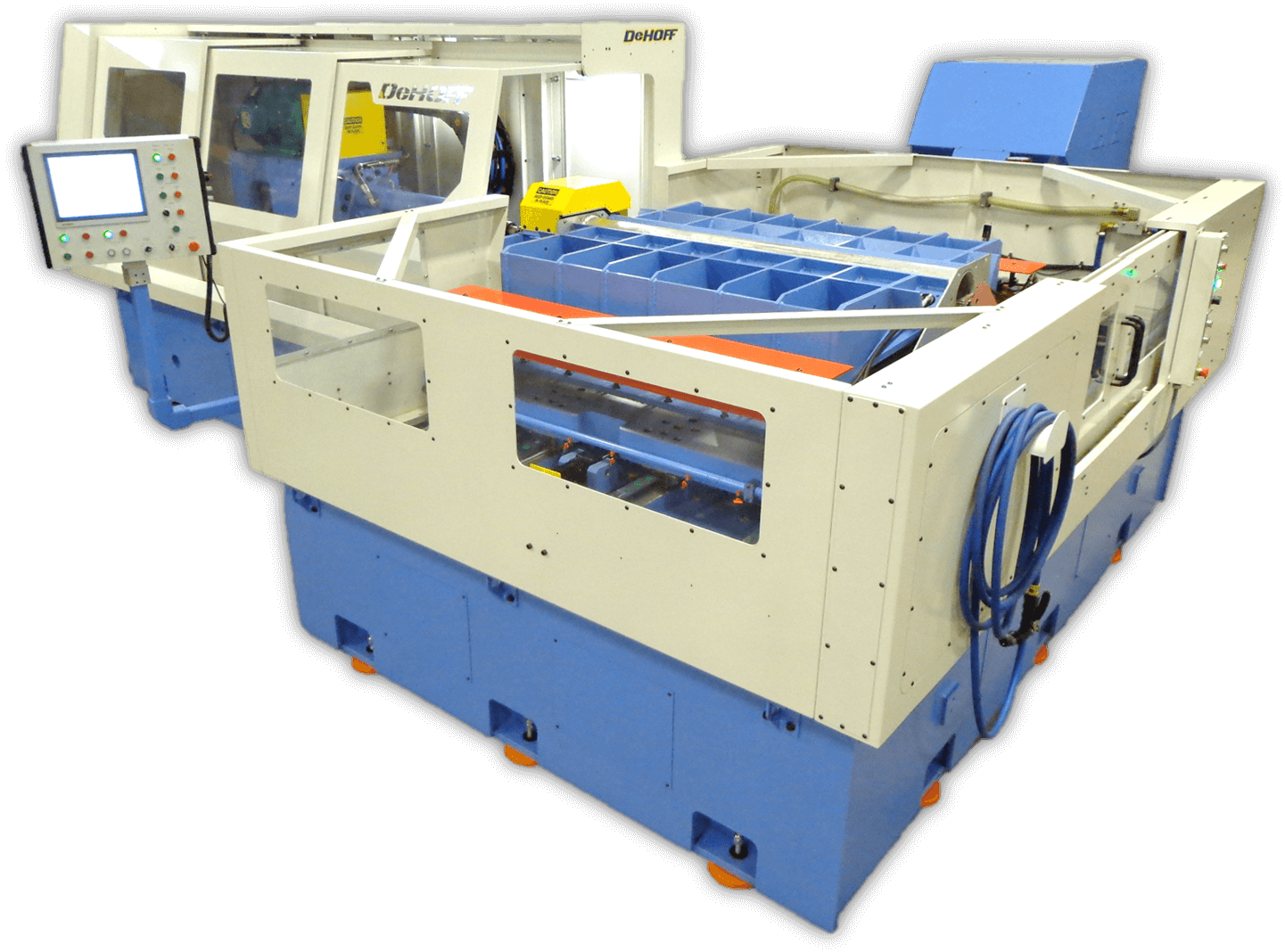

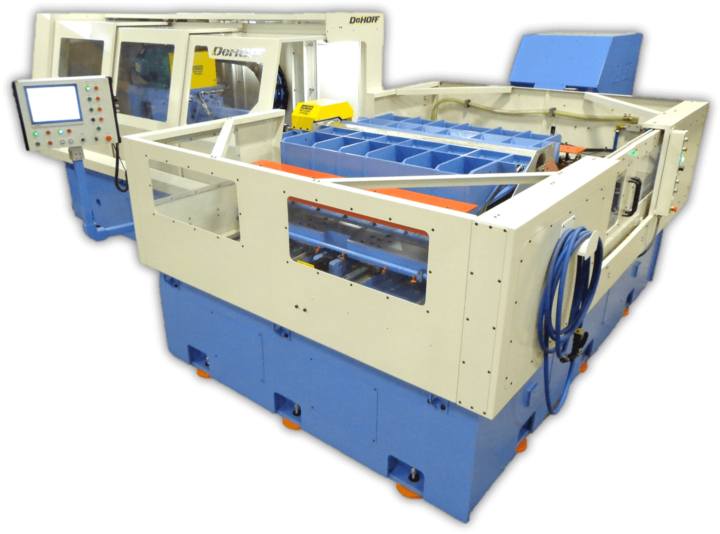

518 Cell 9-Spindle

- Custom machine for gundrilling of scroll compressor drive shafts

- Gundrilling capacity = 0.5 inches (12.7 mm)

- Max depth = 18 inches (457 mm)

- 9 total spindles on 3 machine bases (three spindles on each base)

1036 CNC 3-Axis Boring Machine

- Custom machine for boring the cam journals of automotive engine blocks during rebuild program

- CNC control and knee table with X-axis & Y-axis movement

- Max boring depth (Z-axis travel) of 36 inches (914 mm)

- X-axis travel of 21.5 inches (550 mm), Y-axis travel of 12 inches (300 mm)

- Boring capacity = 1 inch (25.4 mm)

3060 Single-Axis Boring Machine

- Custom machine for boring the bottom housing of a rail car hopper bin

- Boring capacity = 3 inches (76.2 mm)

- Boring depth = 60 inches (1524 mm)

- 40 HP spindle motor with 4-speed gearbox to meet rigorous material removal requirements

- Custom workpiece loading and fixturing system

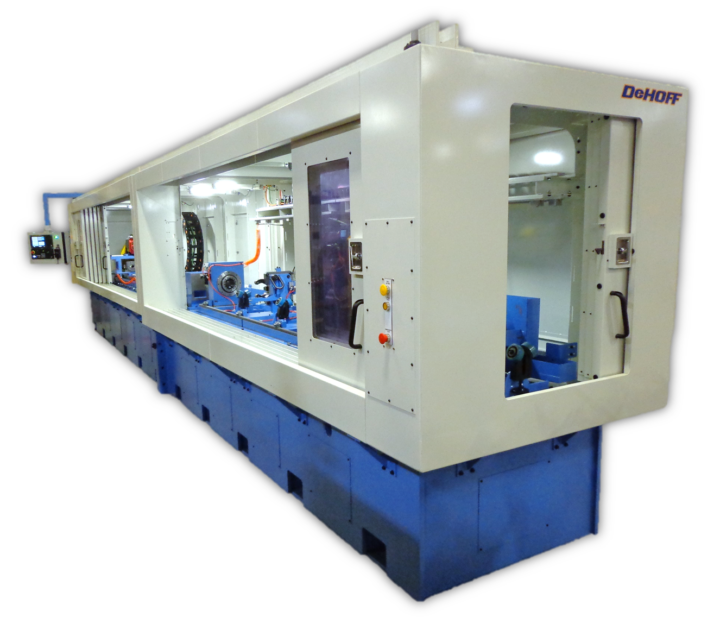

20144 Custom Gundrilling Machine

- Custom machine for gundrilling the aluminum microwave guides for the world’s largest nuclear fusion reactor

- Gundrilling capacity = 2 inches (50.8 mm)

- Gundrilling depth = 144 inches (3658 mm)

- Performs gundrilling, pull boring, roller burnishing, and thread tapping all on a single machine

- Custom workpiece loading and fixturing system